Leading the bioCharge

Biochar is a rapidly growing industry, and Metzler is proud to be in the forefront by offering highly stable char in the Mid-Atlantic region with one of the first industial scale pyrolysis systems in Pennsylvania.

We are pleased to support research projects with our biochar at Penn State University, the University of Connecticut, West Virginia University, Tennessee Tech Poultry, and MASBio funded by USDA's National Institute of Food and Agriculture.

We are also proud to say our pureCHAR and growCHAR are USDA BioPreferred Certifed, Pennsylvania Department of Agriculture PA Preferred and recognized by Pennsylvania Certified Organic.

We appreciate and support the work of the US Biochar Initiative, the US Biochar Coalition and the International Biochar Initiative!

Biochar products we offer

Metzler Biochar is committed to excellence, and it’s why we’ve created

three

different products for you to pick from.

PureChar

Metzler pureCHAR biochar

is produced from local sawmill co-products. It’s straight biochar, and it’s the highest quality around!

growChar

Metzler growCHAR compost

is our proprietary blend of carbon and nitrogen inputs, a nitrogen binder and our pureCHAR biochar to create a soil amendment that significantly increases your soil's water holding capacity and nutrient transfer. The picture to the left shows pots in the fall that received only rain water during the summer. The red pot on the right was filled with half Metzler growCHAR compost and potting soil. The black pot was 100% potting soil. The water holding capacity of growCHAR compost is obvious.

earthchar

Metzler earthCHAR soil blend is local screened topsoil, our growCHAR compost, and our pureCHAR biochar; and it's our answer to your planting projects that need soil to get started.

Reserch and product Development

The Metzler Water Lab

In addition to our proprietary biochar products, we are currently performing Stormwater and Acid Mine Drainage product trials in the Metzler Water Lab.

Biochar for poultry trials

We are pleased to join Jerry Stutzman of Bio Carbon Solutions, Nelson Peachey of Wakefield Farm, Victoria Ayers of Tennessee Tech Poultry and MASBio to prove the benefit of biochar for poultry production.

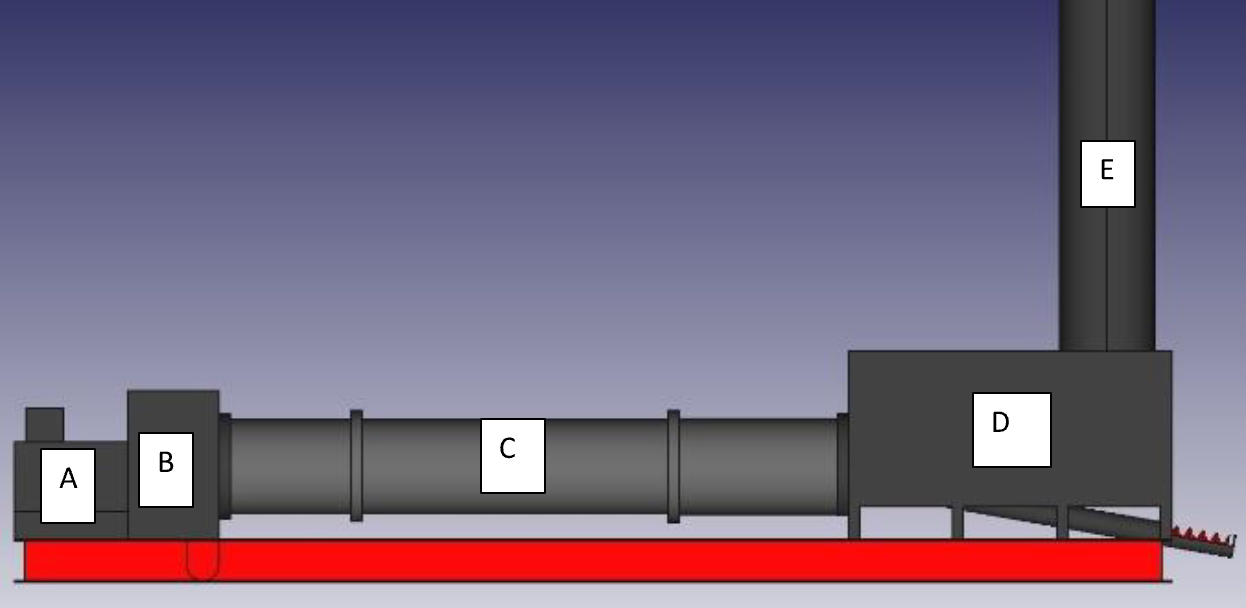

how we make biochar

Different types of biochar exist throughout the industry, making it important to understand how Metzler Biochar makes our char.

We start with wood chips or sawdust from sustainably harvested trees, heated to 1,350 degrees Fahrenheit in an oxygen limited rotary kiln to cook off the volitlas and then quench the carbon particles with water to stop the pyrolysis process leaving a honeycomb of highly stable carbon.

Biochar's homeycomb structure has numerous benefits, including a negative charge to attract nutrients, surface area for adsorption and vessels to hold biologicals or other substances.

We take the production of our biochar one step past making a useful product that sequesters carbon. We use the excess process heat to replace hundreds of thousands of gallons of propane in our firewood drying kilns. We are very proud of this circular economic system.

Find the Right BioChar Product for You!

Metzler Biochar is committed to leading the BioCharGE, so if you’re interested in learning more or placing an order, Metzler Biochar would love to hear from you!